In order to meet the special requirements of customers in the Guam for transportation equipment, the 4 axle 100 ton low loader trailer has undergone continuous optimization of the structural design and accessories upgrades to better ensure reliability throughout the entire transportation process.

In order to meet the long-distance transportation needs of large equipment in the industrial, agricultural and construction fields, the low loader trailer has optimized its structural design. The low center design can effectively reduce the risk of center of gravity shift during low loader trailer 100 ton equipment transportation, while strengthening the structure to ensure stable support for heavy machinery, ultimately achieving a dual improvement in loading stability and long-distance transportation safety.

4 Axle Low Loader Trailer 100 Ton for Sale Near Me in Guam

4 Axle Low Loader Trailer 100 Ton for Sale Near Me in Guam

Overall Dimension: 15800mm*3000mm*3400mm

Load Capacity: 100 ton

Floor Plate: 5mm thick anti slip pattern plate

Side Beam: 300mm high, 8mm thick

Axles: 4 axles, 13ton

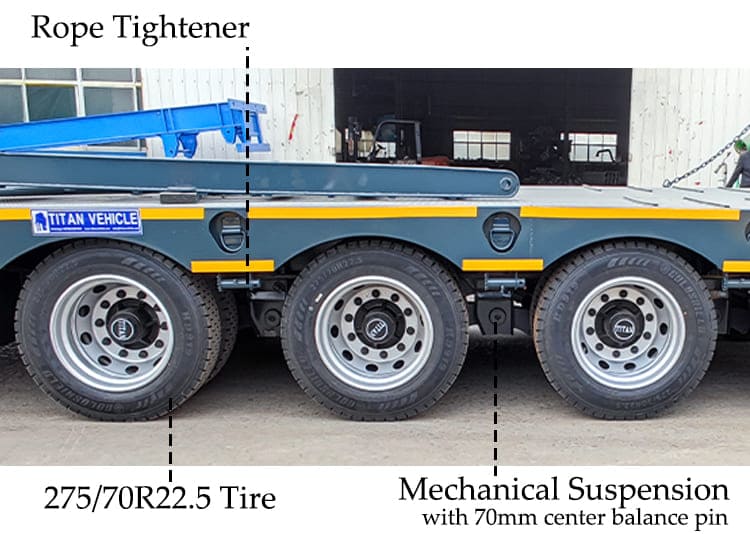

Tire: 16 units, 275/70R22.5

Ramp: Hydraulic Ramp

Landing Gear: 28 Ton

Leaf Spring: 10 layers

Suspension: mechanical suspension

Lamp: LED Lamp

The low loader trailer main beam is constructed of Q460 high strength steel, which significantly improves the compressive resistance and load limit compared to ordinary materials, meeting the performance requirements under heavy-load transportation conditions.

The double-plate reinforced gooseneck structure is designed through mechanical optimization to effectively suppress the deformation of the 4 axle low loader trailer under extreme load-bearing scenarios. The main beam is combined with the thickened floor plate of the low loader trailer 100 ton to expand the effective use area of the loading platform and provide ample operating space for equipment loading and unloading.

The hydraulic ramp, the core loading and unloading component of the 4 axle low loader trailer, adopts angle adaptive adjustment technology. The hydraulic system accurately controls the inclination of the contact surface with the ground, and cooperates with other buffer devices of the low loader trailer 100 ton to ensure the smooth transmission of dynamic loads during the movement of heavy equipment. Operators can master the basic operation process without complex training, taking into account the dual needs of loading and unloading efficiency and safety protection.

The low loader trailer floor plate uses a 5mm thickened anti-slip patterned steel plate, which has stronger support than the conventional 4mm specification. Through the combination of the surface three-dimensional texture design, the low loader trailer 100 ton floor plate forms a multi-dimensional anti-displacement protection system.

The design of the TITAN 4 axle low loader trailer not only enhances the friction coefficient between heavy equipment and the load-bearing surface, but also makes the wear resistance of the bottom plate reach the leading level through structural reinforcement.

16 sets of 275/70R22.5 tires are standardly equipped to form a stable support base for the low loader trailer 100 ton, and customized specifications of 12R22.5 and 315/80R22.5 are provided. Customers can choose according to the special road conditions in Guam.

TITAN low loader trailer tires have been certified by more than 200,000 kilometers in China without any problems. The low loader trailer tires can still maintain excellent grip performance and anti-fatigue characteristics under complex conditions, significantly extending the replacement cycle of components.

The TITAN 4 axle low loader trailer braking system achieves the coordinated optimization of performance and durability through technological innovation. Equipped with 16 ton brake components, the low loader trailer effectively enhances the braking force output, not only significantly improves the emergency braking response sensitivity, but also reduces the braking distance under normal circumstances by more than 5 meters.

The low loader trailer 100 ton pipeline system adopts a combination of high pressure rubber brake air pipes and durable cables, with a design life of 10 years and more than 5 years respectively, which not only reduces the maintenance cost caused by frequent replacement, but also ensures safety redundancy during long-term use through material stability.

The entire system builds a high-reliability braking solution with controllable costs throughout the low loader trailer life cycle for Guam customers through precise matching of structural design and component selection.

The dual modes of container and ro-ro ship are adapted to the global logistics network. The unique full low loader trailer wax spraying process before leaving the factory combined with professional waterproof cover packaging forms a multi layer protection system to effectively resist salt spray erosion and climate environmental impact during sea transportation.